5 Mistakes to avoid when drafting sheet metal parts

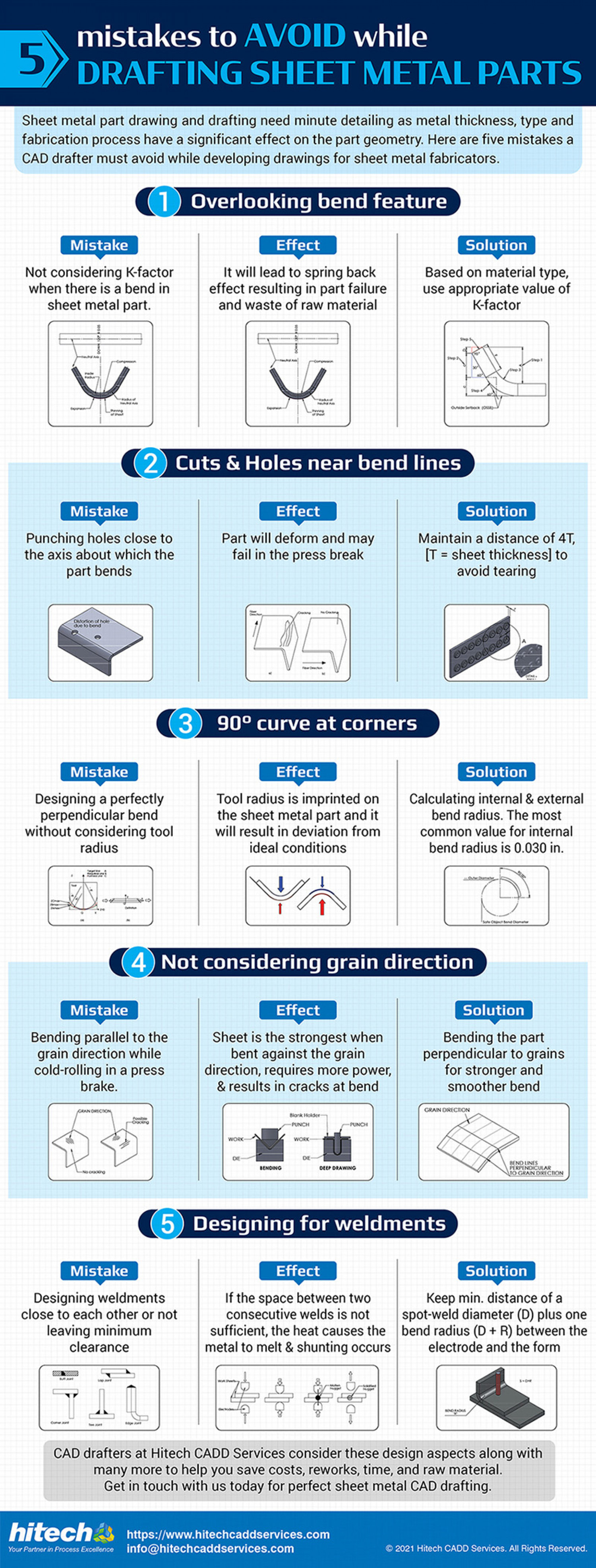

mistakes to AVOID while P2 DRAFTING SHEET METAL PARTS Sheet metal part drawing and drafting need minute detailing as metal thickness, type and fabrication process have a significant effect on the part geometry. Here are five mistakes a CAD drafter must avoid while developing drawings for sheet metal fabricators. Overlooking bend feature Mistake Effect Solution Not considering K-factor when there is a bend in sheet metal part. It will lead to spring back effect resulting in part failure and waste of raw material Based on material type, use appropriate value of K-factor (2) Cuts & Holes near bend lines Mistake Effect Solution Punching holes close to the axis about which the Part will deform and may fail in the press break Maintain a distance of 4T, [T = sheet thickness] to avoid tearing part bends Otorion of hole (3. 90° curve at corners Mistake Effect Solution Designing a perfectly perpendicular bend without considering tool radius Tool radius is imprinted on the sheet metal part and it will result in deviation from ideal conditions Calculating internal & external bend radius. The most common value for internal bend radius is 0.030 in. 4) Not considering grain direction Mistake Effect Solution Bending parallel to the grain direction while cold-rolling in a press brake. Sheet is the strongest when bent against the grain direction, requires more power, & results in cracks at bend Bending the part perpendicular to grains for stronger and smoother bend GRAIN DRECION Bigrk Hokder -PUNCH DE BEND UNES PERPENDICULAR tO GRAIN DIRECTON BENDING DEEP DRAWING (5 Designing for weldments Mistake Effect Solution Designing weldments close to each other or not If the space between two consecutive welds is not sufficient, the heat causes the bend radius (D + R) between the metal to melt & shunting occurs Keep min. distance of a spot-weld diameter (D) plus one leaving minimum clearance electrode and the form CAD drafters at Hitech CADD Services consider these design aspects along with many more to help you save costs, reworks, time, and raw material. Get in touch with us today for perfect sheet metal CAD drafting. hitech https://www.hitechcaddservices.com Your Partner in Process Excellence [email protected] © 2021 Hitech CADD Services. All Rights Reserved.

5 Mistakes to avoid when drafting sheet metal parts

Source

https://www....n=referralCategory

TechnologyGet a Quote